Manufacturing Infrastructure

Victora Industries

Welcome to Victora Industries, a front-ranking Indian manufacturer of Sheet Metal Components, Dies, Tools, Panel Checkers and their Tooling’s. Our flexible approach towards responding to and even anticipating our customers’ needs sets us apart from others.

Through our innovative solutions, world-class engineering standards, and customer-centric processes, we are able to offer a real cost, quality as well as delivery advantage to our customers.

Tool Room

Our tool room has evolved into one of the most highly sophisticated facilities in the country.

Elevator Mfg.

Best-in-class cutting-edge technology satisfy all the stringent international benchmarks.

Our Best-In-Class

Infrastructure

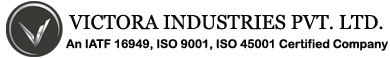

As the crucial area where the entire fabrication process begins, the Press Shop holds great importance in our plants. It is equipped with numerous single and double-acting presses of highly regarded brands such as Erfurt and Stanko , that cater to capacities ranging between 10 T to 1000 T. We also possess special purpose presses fitted out with manipulators.

This machinery is utilized for performing a host of metal forming operations which include deep drawing, blanking, piercing, embossing, fine blanking, impact extrusion, ironing and forming from solid, among others.

Victora Industries takes pride in its state-of-the-art microprocessor controlled spot welding and MIG welding equipment. Bearing testimony to the superlative quality, outstanding productivity and great flexibility it facilitates, our modern weld shop has been approved by Maruti Udyog Ltd. following rounds of rigorous inspection like hammer tests, nugget formation tests, penetration tests and torque tests.

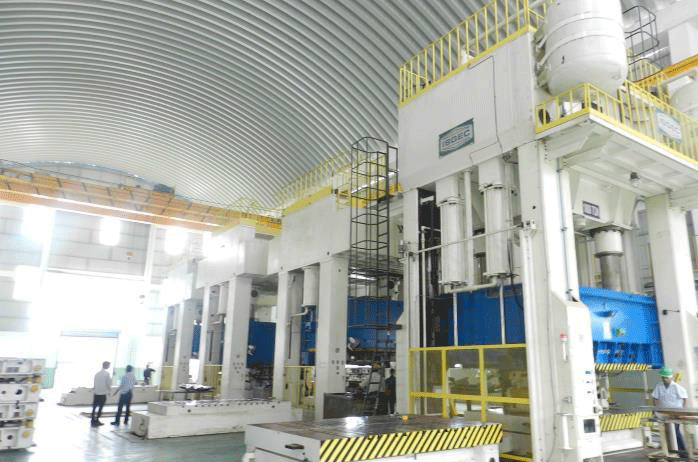

Routine inspections are conducted regularly to uphold the continued integrity of the welding processes. The capabilities of the welding shop have been further enhanced through the installation of several welding robots

A flexible manufacturing system (FMS) makes it possible to automate production with machine tools and thus enable unmanned production and increase the production capacity and utilization rate of the machine tools.

With an FMS, you can manufacture several types of parts simultaneously, and adjust the due dates on the fly. This enables short lead times and small batch sizes, while preserving the benefits of mass production.

Modern design software has re-defined the precision standards of the industry. Being fully committed to remain at the forefront of technology, we make extensive use of computer integrated high end design software which includes CATIA V5R6, Power 3.1 (DELCAM), Autocad 2000 etc.

This allows us to add significant value to the manufacturing chain in terms of offering both a time as well as cost advantage, besides aiding us in the development of new sheet metal press tools, components and products. Our highly experienced and qualified team of tool design engineers is adept at linking critical product specifications and design with the electronic data interchange, thus bringing about substantial savings in costs and time to our customers.

Over the 22 years of being in existence at our premises, our tool room has evolved into one of the most highly sophisticated facilities in the country. It is singularly responsible for meeting all the tooling requirements of the organization’s sister companies. It also manufactures high quality, custom-made precision tooling for a wide range of applications in the industry. Some of the tools designed, manufactured and supplied from this tool room are import substitutes.

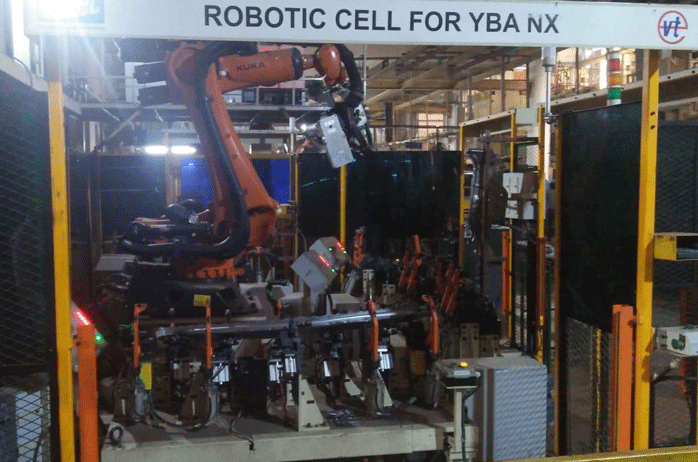

Equipped with an impressive array of more than 60 state-of-the-art machines like precision jig boring, EDMs, copy milling, CNC milling, 2M grinders, wire cut machine etc., the tool room is designed to undertake extremely high-precision and complex manufacturing of press tools, jigs, fixtures, gauges and SPM’s. Our engineering department comprises a strong talent pool of over 65 professionals including tool designers, tool planners and highly skilled die makers.

The fact that Victora Industries has the distinction of being the only Indian manufacturer and supplier of sophisticated elevator door assemblies of various designs to VictoraLifts . Our best-in-class infrastructure housing cutting-edge technology and modern manufacturing and testing facilities satisfy all the stringent international benchmarks of performance and safety.

They are reinforced with high quality semi glossstoving paint, which has proven capabilities to with stand 480 hrs of rigorous endurance exams like salt spray conducted in various labs.

Activity &

Latest News

क्लीन ग्रीन पैनल ने चलाया अभियान, लगाएंगे 25000 पौधे : एस एस बांगा

रक्त की जरुरत कम पड़े इसलिए हेलमेट दे कर कर रहे जागरूक : एस एस बांगा

रक्तवीर स्वयं व् अपने परिवार की सुरक्षा के लिए जरूर पहने हेलमेट : गंगाशंकर

विक्टोरा रक्तवीरो के लिए विशेष स्वास्थ्य जांच शिविर का आयोजन

सुंदरकांड पाठ से व्यक्ति को मानसिक शक्ति प्राप्त होती है : एस एस बांगा

पैदल शब्द चौकी यात्रा का विक्टोरा परिवार ने किया भव्य सतकार

Maruti EV Factory would be proved to be an important milestone for Automobile sector in Haryana : SS Banga

71 Republic Day Celebration

S S Banga honored for his contribution towards environmental protection

All religion were seen in Guru Ghar

Tree Plantation Drive

Deepak Foundation Organized a cultural event

Our Team

Meet The Team

Ut condimentum eros id vulputate ultricies. Cras laoreet ipsum vel imperdiet efficitur. Nullam placerat vulputate justo.

Peter Dean

Managing Director

We take great pride in not just satisfying, but in delighting our customers.

"Doing the Right Things Right the First Time"

Ken Gilbert

Social Media Engagement

Subscription

Keep Up To Date

If you want to contact us about any issue please send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.